Wednesday, October 31, 2012

Watch, Read, Listen, Do: The Pack Expo 2012 Edition

It's the final day of Pack Expo 2012! Just as organizers expected, this year's event has turned out to be record-breaking in terms of attendance. For real-time updates during the last leg of the show, be sure to follow us on Twitter at @BWCnews. For some fun giveaways and good linear motion conversation, visit the BWC team at booth #N-5726.

[ WATCH ] When we express worry about finding a future skilled workforce, we're definitely not talking about the kids participating in FIRST, a global competitive robotics league that teaches kids the art of engineering and building robots. Pack Expo hosted several FIRST leagues, including this one, dubbed team "Mechatronics", from Minnesota, which showed off a robotic prototype the kids plan to use in next year's competitions. We're proud FIRST sponsors ourselves, so you can expect lots more info about the program as the school year progresses.

[ READ ] Packaging Machinery Technology is the magazine published by PMMI, the hosting organization that puts on PackExpo. In it, we found lots of interesting articles about new technologies in packaging and processing, but also some columns that stirred up some provocative discussion. Here's one about sustainability that piqued our interest — it asks if the term "sustainable packaging" may be impractical. A recent report by an industry think tank deemed the term to generic to hold any weight and that the term itself should be "substituted with a more balanced view of efficient packaging." That means streamlined operation spanning the entire product life cycle, from sourcing materials to production, delivery, disposal and recycling. What do you think?

[ LISTEN ] A shortage of mechatronics engineers prevents more advancements in the packaging industry, according to executives from packaging machinery manufacturer Schneider Packaging, who discuss the issue in this podcast published in Packaging World. It's an older podcast, but follow-up articles suggest the lack of mechatronics expertise in the workforce has halted development for some companies. Has your company made efforts to beef up its roster of mechatronics engineers?

[ DO ] This one's easy! Definitely "do" come to our Pack Expo booth N-5726 to check out one of our linear motion product debuts, chat with our guided motion experts and find out just why our motion control systems based on DualVee® Motion Technology remain the best in the packaging processing industry.

Monday, October 29, 2012

Will Bringing More Women Into Manufacturing Fill the Skills Gap?

Monday's Topic in Motion? Women in Manufacturing

Archaeologists recently discovered the ancient remains of a female metalworker dating back to the Bronze Age, according to the Associated Press.

The Austrian museum who announced the discovery reports that the archaeological find is the first of its kind — "the first indication that women did such work thousands of years ago."

Jonnatha Mayberry, an editor for Product Design & Development Magazine, mentions this in one of her recent columns. She writes, "Today, it is well-known that women work in the manufacturing field, but it is also well-known that women are greatly outnumbered by men on the factory floor."

This benchmark in history makes us wonder, why is there still so few women interested in male dominated industries like manufacturing?

In a recently published article on JS Online, writer Rick Barrett points out that although women make up about half of the U.S. workforce, the number of women in manufacturing is declining. He writes, "Today, only 30% of the estimated 14 million Americans who work in manufacturing are women, and only about 15% of the students enrolled in manufacturing-degree programs are women."

Is the perception of manufacturing so negative that women just aren't interested? So bad that fewer and fewer people want to pursue careers in manufacturing? Is this why so few college students enroll in manufacturing programs?

Pamela Kan, president of Bishop-Wisecarver, touches on this in a blog published earlier this morning: When Did Manufacturing Become a Dirty Word? She asks, "What has happened in our country to make our next generation so turned off by the word manufacturing?

Two women "fighting societal norms" were featured in the Star Tribune back in May of this year. Writer Susan Feyder interviewed Lori and Traci Tapani, co-presidents of Wyoming Machine Inc in Minnesota, who left careers in accounting and finance for the "dirty and dull" manufacturing world.

Feyder writes, "They are part of a budding movement to attract more women into an industry that has been a bright spot in the economic recovery. The Tapanis go to schools and job fairs to encourage more students to consider manufacturing, a career they say offers plenty of opportunity and reward. In the process, they hope to serve as role models."

Tell us what you think! Perhaps convincing more women to consider careers in manufacturing will help to close the skills gap? For more resources about women in manufacturing, check out the following sites:

- www.womeninmanufacturing.org: This website offers a host of resources, including information about a summit for women in manufacturing, an informative newsletter and scholarship programs that need support.

- www.manufacturinginstitute.org: Here's an online booklet of best practices for women in manufacturing — a 25-page pamphlet published by the National Association of Manufacturers for women in the industry.

Friday, October 26, 2012

Top Five Twitter Posts: Pack Expo, Molecule Measuring and the Joy of Making Things

Packaging and processing are on our minds as we prep for the big Pack Expo trade show in Chicago next week. Our sales, executive and engineering team will be there in full force with thousands of other suppliers and buyers in the industry. We know it will be a crazy-busy week, which we excitedly anticipate. Keep up with all the chatter by following the #PackExpo hashtag on Twitter ... and be sure to follow us at @BWCnews for pics, posts and other updates live from Chicago!

|

| Credit: Pack Expo |

2. Measuring Molecules with the Naked Eye on Product Design & Development: Evidently, liver cancer causes a slight change in a person's bloodstream, upping the density of a specific molecule by 10 parts per billion, according to PD&D magazine. That tiny difference is tough to notice without state-of-the-art lab equipment. But a new technology created by a professor at Brigham Young University could change that. His "lab on a chip" shows low concentrations of the molecule in question, making it much easier to diagnose the disease. Incredible work!

3. LoPro® Linear Actuators on BWC.com: We asked you on Twitter to name one of our linear guides that come with the actuation options of AT series belt, ANSI roller chain, lead screw and ball screw — LoPro! These actuation linear motion systems are based on our DualVee linear bearings, the building blocks for a wide range of our guided motion products. LoPro units are also available in non-actuated versions. They're durable, tough, cost-effective, low profile and low friction — you get why we call it the "LoPro" now don't you? Click the link to download CAD files free of charge.

4. Linear Guides Help Paramedics Do Their Jobs Quickly, Safely on BWCnews.BlogSpot.com: We were pretty happy to pick up a November copy of Design World and find a story printed about a customer of ours who used one of our linear guides to build a patient handling system for ambulances. In this story, we spotlight the effort of Ray Crawford to help mitigate the problem of handling heavy patients in emergency situations. How did he manage? Click through to read about his novel solution to a growing problem in U.S. emergency response.

5. Introducing Kids to the Joy of 'Making Stuff' on Manufacturing Executive: A factory tour isn't enough to get kids hooked on the joy of manufacturing. To do that, you have to give them something more hands-on, a project of their very own. "The reason is that a predisposition to manufacturing usually comes from the childhood experience of 'making stuff,'" Everette Phillips writes in this column. "And, unfortunately, 'making stuff' has slowly disappeared from school curricula over the past few decades. There are even kindergarten classes and preschools where 'making stuff' has been removed from the day-to-day activities of students." So how to we reintroduce the joy of manufacturing to the next generation? It's a key issue — and the future's at stake. BWC founder Bud Wisecarver started tinkering around with manufacturing at a very early age, building go-carts and other gizmos before he was even a teenager. We'd love to hear your thoughts on this issue! Tell us in the comment box!

Thursday, October 25, 2012

Linear Guides Help Paramedics Do Their Job Quickly and Safely

INVENTIVE SOLUTION Weight gain in the United States has created a number of challenges for healthcare workers and first-responders. One of those challenges is the simple fact that it's more difficult to lift heavy patients into an ambulance in an emergency situation. One of our customers, Ray Crawford, encountered that challenge when a heavyset co-worker slipped and fell at work. Paramedics were unable to quickly lift the gentlemen into the ambulance for transport to the hospital. Crawford addressed the challenge by inventing a heavy duty patient handling system that could lift up to 1,900 pounds.

SHARING THE STORY Our friends at Design World shared this case study in their November issue, which was mailed to subscribers this week. The "Design Notes" feature tells how Crawford came up with the idea for his patient lift, why he chose our [ UtiliTrak® linear guide ] to build the device, and how it could save lives by cutting down on the time it takes to lift and transport heavier patients. It's a critical development in the patient transport industry, a sector forced to make critical changes like this to cope with the changing needs of the American population. Linear motion helps keep first-responders in motion!

[ CLICK HERE to read the feature in Design World ]

SHARING THE STORY Our friends at Design World shared this case study in their November issue, which was mailed to subscribers this week. The "Design Notes" feature tells how Crawford came up with the idea for his patient lift, why he chose our [ UtiliTrak® linear guide ] to build the device, and how it could save lives by cutting down on the time it takes to lift and transport heavier patients. It's a critical development in the patient transport industry, a sector forced to make critical changes like this to cope with the changing needs of the American population. Linear motion helps keep first-responders in motion!

[ CLICK HERE to read the feature in Design World ]

Find Us at Pack Expo: Booth #N-5726

|

| Credit: Pack Expo |

[ PACK EXPO 2012 ] More than 46,000 buyers from around the world will join 1,800 suppliers in Chicago next week for the annual Pack Expo International, a trade show dedicated to showcasing the latest technologies, methods and machinery for packaging and processing. We'll be there at booth #N-5726 to display some guided motion solutions ideal for packaging and processing in virtually any industry.

The event, which takes place from Oct. 28 to 31 at the McCormick Center in downtown Windy City, covers more than 1.1 million square feet of exhibition space. That's a whole lot of room to wander around!

The exhibits include:

- Integrated processing and packaging solutions that drastically increase efficiency and flexibility

- Cutting-edge technologies that serve as a jumping-off point for future product innovation

- Live demos so buyers can see machinery in action to judge capability, adaptability, operation and compatibility with existing technologies

- State-of-the-art product launches, which open the door for safer, more secure, more sustainable and more cost-effective solutions for packaging-processing applications

|

| Credit: Pack Expo |

IN MOTION Bishop-Wisecarver will be at the event to take part in the massive effort to showcase the many technologies that drive the packaging industry. The show is organized by the Packaging Manufacturers Machinery Institute (PMMI), an organization of which BWC is a member. This year's show is slated to be the largest Pack Expo in a decade, per PMMI.

"We are extremely excited to be exhibiting at Pack Expo this year as a member of PMMI," BWC Project Engineer Brian Burke told us recently. "Our innovative products are ideally suited for packaging applications, including corrugated handling, case erecting and case packing applications."

NEW DEMOS, NEW IDEAS Since exhibiting last year, BWC has launched new products and come up with new ideas to serve the packaging-processing industry. One of those innovations is our recently launched MadeWell® Radial Wheel, a bearing we designed as a cost-effective solution for applications with specified radial loading conditions.

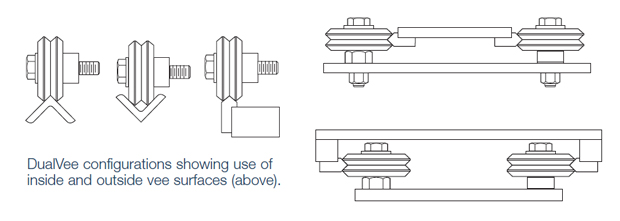

One of the reasons we make a point of going to Pack Expo is because our guided motion technologies are ideal for the packaging industry — a well-known ability to withstand debris-laden environments. The double vee-edge design of our bearings and related guided motion systems offer an inherent self-cleaning action that sloughs away debris like paper, cardboard, wood, metal shavings, glass, plastics and other contaminants.

“Bishop-Wisecarver has strong ties to the packaging industry and decades of experience imagining solutions for all kinds of applications inherent to the industry,” said Pamela Kan, President of Bishop-Wisecarver. “I look forward to attending the show and speaking with our customers one-on-one.”

[ Click here to make an appointment with one of our sales reps or engineers at the show ]

Tuesday, October 23, 2012

Watch, Read, Listen, Do: Invention, Innovation and Manufacturing in the 2012 Elections

We kicked off October celebrating the first-ever National Manufacturing Day, and since then, we've been mulling over thoughts of manufacturing, engineering, invention and their place in our increasingly interconnected global economy. BWC carved its own place in manufacturing history for several reasons. As we close in on a new year and we barrel into another presidential election, we reflect on changes and advancements that 2012 brought to us. We also start thinking about how that sets us up for the last quarter and, very soon, a new year. Here's a look at some multimedia resources that keep those thoughts in motion.

[ WATCH ] "There isn't one material thing that you can think of that wasn't invented by a toolmaker," Bud Wisecarver quips at the start of this web series, "Life of an Inventor." We uploaded the interview footage a couple years ago, but it's worth sharing again because of its timeless insights. Every physical thing we make in society starts with an inventive idea, looking at the world from an original perspective and coming up with a novel solution. That's the spirit of invention that drives the fields of engineering and manufacturing. Who is your role model toolmaker?

[ READ ] What economic policies would make for a better outlook for manufacturing in the U.S. and abroad? How can we boost the manufacturing sector? Close the skills gap? General Electric created this online "Ideas Lab" to collect thoughts from inventive minds all over the world. This online forum draws inspiration and input from thought leaders in a variety of industry sectors to discuss today's hot-button issues from a unique perspective. Read columns, reports and other forms of research on this online hub of conversation, which centers around manufacturing, labor and technology. You could also plug your email in to get updates from this place to convene, discuss and spawn new ideas.

[ LISTEN ] True patriotism and real charity aren't confined to feelings of pride of country or sympathy for others. They're acted out by giving. NPR released a podcast about a program both patriotic and charitable. Reportedly, four manufacturers promised to pay for training for military veterans to prepare them for jobs in the manufacturing sector. The money will go toward a group called Get Skills to Work Coalition, which aims to equip 15,000 former soldiers for the manufacturing workforce. We salute that!

[ DO ] The U.S. presidential election lies only weeks away, Nov. 6, and the conversation surrounding manufacturing has been more heated than ever. That's why it's important for stakeholders in the manufacturing community to make their voice heard. So our "DO" in this edition is, well, to go out and vote! The National Association of Manufacturers compiled a helpful online resource in this "Election Center" on their website. Watch the video first, then copy the HTML code to put the "vote" badge on your website.

Friday, October 19, 2012

Top Five Twitter Posts: Election Season, Acoustic Levitation and Falling Meteors

Friday's here ... and with it comes our weekly retrospective of what's up on Twitter. Our CEO is busy tweeting up a storm from the PTDA Industry Summit in Dallas this week, and a host of other tweeps have broken news about new industry developments or have shared interesting discussions about educating a future manufacturing workforce. As usual, we found plenty to talk about. Here's a sample of what caught out interest this time around. Follow us for future bon mots and conversations at @BWCnews!

|

| Credit: League of Women Voters |

2. An Acoustic Levitation Chamber on YouTube.com:Evidently, in 1987 some NASA researcher designed an acoustic levitation chamber, basically a cube affixed to a few speakers that emanated sound waves at a resonance strong enough to actually lift light objects. "The research was used to show the effects of micro-gravity conditions that exist in the space shuttle environment in orbit," he writes. Fascinating — particularly when you consider this experiment dates back a quarter century! For a quick explanation of how acoustic levitation works, check out this article on HowStuffWorks.com, which does a find job explaining the science of sound and how it's actually a tangible, physical presence.

3. School Reform, But From Whose Perspective? via Education Week: Generally, we develop our worldviews based on our own experiences. So why are the majority of high-profile public school "reformers" products of private education? Here's an interesting take on the issue, which begs the question of how we revitalize science, tech, engineering and math (STEM) education in our critically underserved public schools. Bishop-Wisecarver founder Bud Wisecarver and his daughter (now-BWC President Pamela Kan) are tireless advocates of promoting STEM education. It's that perspective that motivates us to get involved in programs like FIRST Robotics, engineering internships or local high school science fairs.

|

| Credit: Phil Terzian via San Jose Mercury News |

5. 65 Digital Media Resources You May Have Missed via Mashable.com: We're huge fans of technology consultant Scott Klososky, who suggested this article on Twitter earlier in the week (and who happens to be a speaker at the PTDA summit today). It's a super-useful summary of some key changes in the social media landscape in recent weeks, from LinkedIn updates that could boost business to tips on how to supercharge your Twitter searches and marketing efforts. Thanks for the heads up, Scott! We'll definitely check it out!

Wednesday, October 17, 2012

Watch, Read, Listen, Do: Precision Rings, Economic Forecasts and Something Worth Your Vote

The BWC team is busy this week meeting with transmission and motion technology distributors in both Canada and Texas. The Power Transmission Distributors Association meets in Dallas, TX, at the same time the Association for High Technology Distribution gathers for its annual fall meeting in Quebec. It's bound to be a productive week! To keep up with the action at PTDA, you can follow BWC President Pamela Kan on Twitter at @peekan ... or us at @BWCnews!

[ WATCH ] We launched a new video series designed to give you a quick overview of guided motion technologies — a shot of product info in 60 seconds or less. Here's the first installment, a clip about our Hepcomotion® PRT2 rotary guides, an offering of single-edge and double-edged rings, segments and slides. PRT2 is available in stainless steel, are low-friction, up to task in extreme environments and can configure into virtually any track shape. Think you can become a PRT2 expert in less than a minute? Give it a shot!

[ READ ] Since PTDA's on the brain, we've been poking around their website to find interesting articles to share. We came across this page showcasing the latest market forecast report. It's a pretty extensive study on the industrial manufacturing industry with some predictions about the next quarter. This particular report examines some of the following topics:

- The the latest macroeconomic climate news in the U.S.

- Growth in the Canadian economy

- The state of end-user markets compared to the overall economy

- What vertical markets are on the rise/decline

- The cyclical relationships that apply to the markets served by your company

[ LISTEN ] Synchronicity and predictability are key factors to weigh when choosing an industrial control unit. So it's important for field mechanisms to have network-wide functions to activate output and capture new data, among other things. Our friends at Design World are hosting a webinar next week to explain how the distributed clock controls in EtherCAT work to fulfill all those functions. Click through to register in advance!

[ DO ] Election season has folks on both sides of the aisle brandishing conflicting ideas... But here's an election that's friendly to people from any political background. We're talking about the "Leadership in Engineering" awards by Design World in which we have a nomination for in the motion control category. If you support what we do, feel free to cast your vote to commend our 60 years as pioneers of innovation and guided motion manufacturing. Thanks in advance for your support!

Monday, October 15, 2012

#MotionMonday: Networking with Motion Control Distributors

A TALE OF TWO CITIES The BWC team will divide and conquer this week, with some heading to Dallas, TX, and others to Quebec City in Canada for a couple industry events that aim to strengthen relationships between manufacturers and distributors. The Power Transmission Distributor Association Summit and the Association for High Tech Distribution both host fall meetings/summits at the same time, Thursday through Friday this week. Our Vice President of Sales, Mike McVeigh, will attend the AHTD meeting while BWC President Pamela Kan will join her peers at the PTDA summit down south.

Both events report a boost in attendance over recent years, they told us. Part of that could be because of the improved economy, part of it because more people see the value of fostering a healthy supplier-distributor network.

“The industry summit continues to be the most valuable benefit for our members,” PTDA Executive Director Ann Arnott says. “Those who have attended in the past understand how much work gets done — quickly and thoroughly — in just the two-and-a-half days of the event.”

PTDA Kan said she looks forward to meeting with distributors at the PTDA's manufacturer-distributor idea exchange, a time set aside at the summit to give members a chance to meet new companies, get acquainted with new products and, well, exchange ideas.

Some of the PTDA summit attendees will participate in a golf tournament and 144 of them will receive a handy "survival kit" we put together: a Ziploc baggy with a WD-40 pen, some duct tape and a microtool.

Among the key speakers at the PTDA summit is one of our favorites, leading technology expert Scott Klososky.

AHTD Meanwhile, during the same time, McVeigh will join AHTD members at the swanky Fairmont Le Chateau to learn more about the event's theme to "expand your borders."

“These events allow us to get closer with distributors and explore ways to help each other increase revenue, to renew past relationships and develop new ones,” McVeigh said in a statement we published this morning. “The speakers are always relevant and provide insights that initiate conversation and thought.

To learn more about PTDA, go to www.ptda.org. For further info on AHTD, go to www.ahtdmembers.org. For a list of upcoming events for Bishop-Wisecarver or to make a one-on-one appointment, go to www.bwc.com.

Both events report a boost in attendance over recent years, they told us. Part of that could be because of the improved economy, part of it because more people see the value of fostering a healthy supplier-distributor network.

“The industry summit continues to be the most valuable benefit for our members,” PTDA Executive Director Ann Arnott says. “Those who have attended in the past understand how much work gets done — quickly and thoroughly — in just the two-and-a-half days of the event.”

PTDA Kan said she looks forward to meeting with distributors at the PTDA's manufacturer-distributor idea exchange, a time set aside at the summit to give members a chance to meet new companies, get acquainted with new products and, well, exchange ideas.

Some of the PTDA summit attendees will participate in a golf tournament and 144 of them will receive a handy "survival kit" we put together: a Ziploc baggy with a WD-40 pen, some duct tape and a microtool.

|

| "Does It Move?" BWC's Special PTDA Giveaway: Use this flow chart to decide whether you need WD40, duct tape, or a screw driver. |

AHTD Meanwhile, during the same time, McVeigh will join AHTD members at the swanky Fairmont Le Chateau to learn more about the event's theme to "expand your borders."

“These events allow us to get closer with distributors and explore ways to help each other increase revenue, to renew past relationships and develop new ones,” McVeigh said in a statement we published this morning. “The speakers are always relevant and provide insights that initiate conversation and thought.

To learn more about PTDA, go to www.ptda.org. For further info on AHTD, go to www.ahtdmembers.org. For a list of upcoming events for Bishop-Wisecarver or to make a one-on-one appointment, go to www.bwc.com.

Friday, October 12, 2012

Product Spotlight: Heavy Duty Linear Slides

A few of our HepcoMotion® linear slide product offerings were built for heavy duty applications, systems that carry thousands of pounds over long lengths and require the utmost durability. In today's post, we'd like to highlight a few tough products that offer motion without limits.

HDLS These heavy duty linear slides (thus, the "HDLS" acronym) are driven by an AT style belt and come in either narrow or wide units. The narrow version is more tall than wide, which makes it more rigid. The wide, on the other hand, works better for applications with high moment loads. Both versions include right, left and dual output shafts. You could also affix gear boxes to drive two parallel systems. Shock absorbers and rubber buffers are not standard but are available upon request.

To help you visualize how this guide works, take a look at this heavy duty door handling system pictured below. This unit incorporates two angled type HDLS units, one with a geared motor and linked with a drive shaft. The lifting mechanism is suspended from a Hepco HB25 beam. [ Click any of the images to view the product pages for further info ]

HDCB This heavy duty compact beam (which we shorten to HDCB for simplicity's sake) is a versatile addition to our heavy duty product offering. The product's compact aluminum beam section can mount slides on all four corners, if needed. The HDCB can be used as a single-axis unit, but can also be made into a two-stage telescopic axis. The curved recess function allows the user to include a ball screw drive. If the application calls for it, though, this type of compact beam can be rack-driven by placing a rack on the back face of the single-edge beams. Standard carriage plates are simple to install on this unit, which comes in maximum single-piece beam lengths of 6 meters.

HDCS This ball screw-actuated version of heavy duty linear beams is based on the previous HDCB with single-edge vee guides. HDCS beams come in lengths up to 2,740mm with 025mm ball screws. Easy-to-reach lubrication points on the ball screw cut maintenance time and ensure long life. For harsh environments, many users request bellow covers to protect the unit.

Have a question for our engineers? Leave comments below! Many of our blogs are specifically based on your requests. We meet with our engineers once a week on the topics you choose. You can also send us an email at info@bwc.com for more information.

HDLS These heavy duty linear slides (thus, the "HDLS" acronym) are driven by an AT style belt and come in either narrow or wide units. The narrow version is more tall than wide, which makes it more rigid. The wide, on the other hand, works better for applications with high moment loads. Both versions include right, left and dual output shafts. You could also affix gear boxes to drive two parallel systems. Shock absorbers and rubber buffers are not standard but are available upon request.

To help you visualize how this guide works, take a look at this heavy duty door handling system pictured below. This unit incorporates two angled type HDLS units, one with a geared motor and linked with a drive shaft. The lifting mechanism is suspended from a Hepco HB25 beam. [ Click any of the images to view the product pages for further info ]

|

| (Click for larger view) HDLS in a door handling application. |

HDCB This heavy duty compact beam (which we shorten to HDCB for simplicity's sake) is a versatile addition to our heavy duty product offering. The product's compact aluminum beam section can mount slides on all four corners, if needed. The HDCB can be used as a single-axis unit, but can also be made into a two-stage telescopic axis. The curved recess function allows the user to include a ball screw drive. If the application calls for it, though, this type of compact beam can be rack-driven by placing a rack on the back face of the single-edge beams. Standard carriage plates are simple to install on this unit, which comes in maximum single-piece beam lengths of 6 meters.

|

| (Click for larger view) Cutaway line drawing of an HDCB beam. |

HDCS This ball screw-actuated version of heavy duty linear beams is based on the previous HDCB with single-edge vee guides. HDCS beams come in lengths up to 2,740mm with 025mm ball screws. Easy-to-reach lubrication points on the ball screw cut maintenance time and ensure long life. For harsh environments, many users request bellow covers to protect the unit.

|

| (Click for larger view) HDCS, a HepcoMotion ball screw-actuated heavy duty linear slide. |

Have a question for our engineers? Leave comments below! Many of our blogs are specifically based on your requests. We meet with our engineers once a week on the topics you choose. You can also send us an email at info@bwc.com for more information.

Top Five Twitter Posts: A Manufacturing Makeover, Pack Expo and Supersonic Flying Wings

We're pleased to announce that we'll be attending a couple industry summits and trade shows next week: AHTD 2012 Fall Meeting in Quebec, Canada, and the annual PTDA Industry Summit in Dallas, TX. Prepping for the two events has made this week zip by in record time. But we're eager to share with you news and views that flickered across our Twitter feed since Monday. To keep up with us in the future, follow us at @BWCnews. Happy Friday, friends!

1. Manufacturing Needs a Brand Makeover via Industry Week: Eileen Markowitz, President of Thomas Industrial Network (which owns ThomasNet.com), says the U.S. manufacturing sector needs to re-evaluate its branding. "When I was growing up, it seemed like everyone believed the United States manufacturers made the greatest products in the world," she writes. "From our home appliances to our cars, we all chose Made in America products for their quality and value." Today, she says, the industry has lost much of that allure, which has made it difficult to recruit and fill skilled manufacturing jobs. What do you think about the "branding" of American manufacturing?

2. BWC to Exhibit at Pack Expo 2012 in Chicago on www.bwc.com: That's right! We'll join hundreds of other exhibitors in the packaging processing and machinery industry to exhibit at the 2012 Pack Expo trade fair in Chicago. Our CEO Pamela Kan will attend this one, so stop by to say hi. We will showcase our new MadeWell® Radial Wheels as well, so be sure to ask to see that demo at booth # N-5726.

3. Supersonic Flying Wing Nabs $100K From NASA via Tech News Daily: We love 90 degree angles! We learned this week that NASA gave a six-figure dollar amount to fund manufacturing an aircraft shaped a lot like a four-point ninja star. The aircraft flies faster than the speed of sound by making a simple 90-degree turn in midair.

4. Packaging and Recycling Industries Work Together in Packaging Digest: Since we're key players in the packaging and processing industry, we keep abreast of the latest packaging-related news. This article we found interesting because it talks about how recycling and packaging are doing more to team up, in part because the recycling industry is largely supported by packaging. Click through to read more about the "sibling-like" relationship between the two manufacturing/processing sectors.

5. Manufacturing Day Infographic from the U.S. Census Bureau: The census bureau joined hundreds of other manufacturers in the U.S. and across the globe in celebrating the first annual Manufacturing Day last week. The federal agency put together this infographic about the industry to illustrate the place of manufacturing in the American economy. Interesting stats here!

|

| Credit: U.s. Census Bureau |

Tuesday, October 9, 2012

Explore the Guided Motion Possibilities of Linear Bearings with Applications Engineer Dan Fletcher, Coffee Chat Part III of III

ROLLING RIGHT ALONG Today, we're wrapping up our ongoing conversation about DualVee Motion Technology with one of our Applications Engineers, Dan Fletcher. Click here to read Part I about precision and speed, or Part II about tolerances and lubrication.

Have questions for Dan about this coffee chat series? Send him an email at danf@bwc.com!

SIZING TIPS DualVee guide wheels come in a range of diameters to support different load specs. For example, a single 75 mm 4XXL double-vee wheel can hold radial loads of 3,215 lbf. A single 150 mm vee bearing wheel has a radial load capacity of as much as 11,240 lbf while a four-wheel carriage can handle double that.

What do you need to consider when calculating load evaluations?

Dan: Evaluating guide wheel loads is relatively easy, but it is important to clearly understand the conditions under which they will be used. Start with determining whether the loads are radial or axial (see image).

What factors affect the service life of guide wheel systems?

Dan: Several factors influence the service life of guide wheel systems such as size of the bearing elements, relative spacing, and the orientation, location and magnitude of the load. There's a simple method you can use that will estimate the load/life relationship by defining the loading conditions. The equations (below) are based on clean and well-lubricated track conditions. The ratings and calculations are theoretical values based on ideal conditions. Most applications will involve less than fully optimum conditions, and in a situation where a particular size bearing may appear marginal in capacity, selection of the next larger bearing size is recommended.

How do you calculate load/life relationships?

Dan: To start, you have to understand three things: The principles of statics, the ability to use free-body diagrams, and the know-how to resolve externally applied forces on a carriage assembly into the axial and radial reaction forces at each linear guide wheel. The most heavily loaded bearing in the design will determine the life of the guide wheel system.

What steps go into sizing and choosing a guide wheel assembly?

Dan: That can be done in three steps. This includes figuring out the radial and axial loads, how much weight is applied to the most heavily loaded bearing, and applying those variables to make up for speed, environment, shock, and vibration.

[ FREE DOWNLOAD ] White Paper: Guide Wheel System Properties, Selection & Sizing

Is all of this difficult to do?

Dan: Only a simple understanding of engineering principles and force analysis is needed to properly evaluate and size these types of systems.

Monday, October 8, 2012

#MotionMonday: Scenes From Motek International Trade Fair for Assembly, Handling Technology and Automation

MOTEK 2012 Exhibitors in the assembly, handling technology and automation industries met for the 31st annual Motek International Trade Fair in Stuttgardt, Germany, this week to witness the latest advances in those fields. Bishop-Wisecarver Corporation President Pamela Kan and her executive team were among the 30,000 people attending the event, which pulls in attendees from more than 100 countries.

To learn more about recent advances in industrial components, sub-assemblies and other automation solutions for manufacturing, testing, assembly, intralogistics and packaging.

Mechatronics and research and development are some of the main themes at Motek this year, according to organizers. The theme encourages visitors to "look beyond the obvious," they say, and to think of ways to pack in "more expertise in less time."

SNAPSHOTS We compiled a handful of Instagram snapshots Pamela took from the show, which runs through Thursday. We look forward to seeing more photos from her trip! Follow her on Instagram to see live updates from Pamela at @pamelakan.

[ Click here to see some of our products used in assembly, handling, and automation applications ]

To learn more about recent advances in industrial components, sub-assemblies and other automation solutions for manufacturing, testing, assembly, intralogistics and packaging.

Mechatronics and research and development are some of the main themes at Motek this year, according to organizers. The theme encourages visitors to "look beyond the obvious," they say, and to think of ways to pack in "more expertise in less time."

SNAPSHOTS We compiled a handful of Instagram snapshots Pamela took from the show, which runs through Thursday. We look forward to seeing more photos from her trip! Follow her on Instagram to see live updates from Pamela at @pamelakan.

[ Click here to see some of our products used in assembly, handling, and automation applications ]

Friday, October 5, 2012

Happy #ManufacturingDay: Top Five Twitter Posts

Today is National Manufacturing Day, a time to talk about, demonstrate and reflect on the importance of manufacturing to the economy, both domestic and global. Bishop-Wisecarver has been part of America's manufacturing history for more than 60 years now, so we're celebrating today! Hear, hear to the inventors, engineers, and makers-of-things that fuel the workforce and create jobs for thousands of people in the U.S.

NAM says a recent study showed that 600,000 manufacturing jobs are left unfilled because companies can't find workers with the required skills. Hopefully today's focus will educate people about the field and about how a manufacturing job can offer a rewarding career and long-term security. Join the manufacturing-related conversation with us at @BWCnews!

1. The Newest American Idol (Manufacturing) on Manufacturing Innovation Blog: What if the public was as obsessed with manufacturing as they are with celebrity pop culture? What if they watched the Science Channel's "How It's Made" as obsessively as they did "American Idol?" Part of the goal of Manufacturing Day is to change that, to "highlight the importance of 'making things' to the American economy," per this article, and to shift attention to the many job opportunities in modern manufacturing. That's a cause we can get behind!

2. First Annual Manufacturing Day Highlights Economic Importance, Opportunities via ThomasNet.com: The National Association of Manufacturers helped co-produce today as a designated national Manufacturing Day. The event underscores the importance of the industry to the economic engine, NAM says. Manufacturers across the country will host open houses, career workshops and other events to commemorate this Friday, Oct. 5.

3. A Minute of Motion — Rotary Motion Guide on YouTube: How much can you learn about our HepcoMotion® PRT2 precision ring and track in 60 seconds or less? Watch this video to find out!

4. BWC History on bwc.com: Last Friday, we celebrated Bishop-Wisecarver Corporation's 62nd birthday. It's amazing to look back at this timeline and see how many things this Bay Area-based manufacturer has contributed to the world of mechanical engineering. Bud Wisecarver, BWC's founder, is part of manufacturing history in this country ... and as such, a huge proponent of the cause behind Manufacturing Day. Read up on the origins of BWC right there on our website.

5. Manufacturing is Looking Good on Manufacturing Innovation Blog: The kind folks who pen the Manufacturing Innovation Blog (one of our faves, by the way), put together this handy infographic to help you visualize the state of manufacturing in the U.S. and "the disconnect between perception and facts" about the industry. Pretty interesting!

|

| Credit: Manufacturing Innovation Blog |

Thursday, October 4, 2012

Explore the Guided Motion Possibilities of Linear Bearings with Applications Engineer Dan Fletcher, Coffee Chat Part II of III

[ This is Part II of a three-part series on guided motion basics — read Part I here ]

TOLERANCES AND LUBRICATION We're picking up from yesterday's conversation about the form, function and range of environments that DualVee Motion Technology® is built to handle. Today, we'd like to talk about the tolerances and lubrication of the double row angular contact bearing. We continue the series with one of our Applications Engineers, Dan Fletcher.

Tell us about DualVee's tolerances — what are the contact bearing's basic capabilities?

Dan: Most of the time, an off-the-shelf guide wheel system should meet positioning tolerances of +/-0.005 inches, depending on the surface. If the track is hardened and ground to specific tolerances, the bearing could then meet positioning tolerances of +/-0.001 inches.

More often than not, double row angular contact bearing designs rely on the track's base mounting surface to maintain accuracies and tolerances. If the mounting is stiffer than the track, the track will adapt to the flatness, straightness, parallelism and twist — if designed with that in mind. If the design doesn't need to be that precise, the mounting surfaces don't have to be as demanding, which lessens the overall cost of the project.

Can you elaborate?

Dan: Well, for example, if the application needs tolerances of +/-0.004 inches, you can bolt a guide wheel system to a sort-of uneven surface and a carriage will still work and run smoothly. Time spent on preparing the surface is minimal, though, and so is the cost and time spent to install it. But if you need +/-0.001 inches for an application, that just means spending more time to prepare the mounting surface, which raises the price.

Why is lubrication important?

Dan: As with many bearing systems, proper lubrication will enhance service and product life.

What if lubrication isn't a requirement for an application?

Dan: If that's the case, the guide wheels are still often a preference over alternative motion technologies. Lots of cleanroom applications in the medical industry demand dry rollers to cut out possibility of contamination, to cite one example.

[ Join us next week for the final installment in this series, where we talk about DualVee Sizing Tips ]

The Business of Being Green

We're a Bay Area Green Business-certified manufacturer, so when we received a certificate saying a tree was planted in our name, that really made our day!

We're a Bay Area Green Business-certified manufacturer, so when we received a certificate saying a tree was planted in our name, that really made our day!On the left, the certificate says that because we bought a biodegradable eco-friendly promotional item through Eco Promotional Products, Inc., they planted a tree on our behalf.

That tree, they say, will suck up 50 pounds of pollution from the atmosphere every year while exhaling life-giving oxygen.

Another cool thing about this company is that, like our own, it's a woman-owned business certified through WBENC (Women's Business Enterprise Council).

[ Click here to learn more about our green business and woman-owned certifications ]

Wednesday, October 3, 2012

Explore the Guided Motion Possibilities of Linear Bearings with Applications Engineer Dan Fletcher, Coffee Chat Part I of III

PRECISION AND SPEED These two factors are critical when spec'ing what linear guide system works best for your application. Many other variables must be considered as well, such as environment type, duty cycle, length, temperature and payload weight. To help explain how to choose the right guide wheel system for you, we turned to one of our applications engineers, Dan Fletcher.

What makes the DualVee® wheel stand out from other linear motion technologies?

Dan: In each of the three major linear motion technologies (profile rails, round rails, and guide wheels), ball bearings recirculate. In profile and round rails, however, the bearings ride on the guide rail and are exposed to any of the contaminants that may settle on the rail. The bearings in a 90° double-vee guide wheel are self-contained and isolated from the environment, so there is no contact between the bearings and the rail.

Why is the actual shape and form of the wheel important?

Dan: Most contaminants that settle on vee guide rails are swept away when the wheel passes over the rail. When the wheel spins at a constant speed, the diameter at the inner vee travels at a slower rate than the diameter at the outer vee, causing a velocity gradient that pushes the debris outward.

How did DualVee Motion Technology come about?

Dan: The double-vee design was originally developed in 1967 as a replacement for flat rollers on machinery at a fertilizer packaging plant, where debris from the processing operations continuously clogged the bearings, causing equipment to shut down. The 90° double-vee approach, with its inherent wiping action, proved ideal.

What are some other advantages of choosing a DualVee-based linear motion system?

Dan: Those self-contained ball circuits have other, lesser-known advantages, too. The containment can cut noise levels by up to 20 percent in some applications compared to alternative re-circulating technologies. The DualVee runs smoothly for several reasons. For one, it has a constant radius ball bearing path. Its carbon, stainless steel and composite components also contribute to its effortless movement.

What about noise?

Dan: The steel versions are slightly louder, but permit fast acceleration, up to 5 gs, and speeds up to 5.5 m/s. For quieter motion, and a more economical option, the polymer versions works well in chemical-exposed settings and lighter-load applications.

[ Read about DualVee's tolerances and lubrication requirements in Part II—tomorrow! ]

Monday, October 1, 2012

Regional Perspectives on Manufacturing: Your Motion Monday Update

|

| Credit: Pamela Kan |

NMMI was born out of a federal push to create a network of manufacturers and close the gap between research and development activities and the actual production of technological innovations. The effort is in the idea-sharing stage right now and the prospect of funding still uncertain. But Pamela said it's encouraging to be part of the conversation.

"I am really honored to have been a part of the workshop and participate as a panel member for the discussion on 'Challenges and Solution for Sustainable Engagement Across the Manufacturing Ecosystem,'" she told us. "I look forward to reading the comment from all four workshops once completed. It is an exciting concept and I am very encouraged to see the United States President focusing on the importance of manufacturing to our country and our economy."

[ See some of what she tweeted from the event on Twitter ]

|

| Panelists at the Sept. 27 event. Credit: Marc Madou |

These IMIs all over the country will help connect companies, encourage them to collaborate and put them in touch with universities and other research/science organizations to beef up domestic manufacturing and assembly, according to NMMI. Part of the goal, in addition to improving existing manufacturing businesses, is to plan on how to train a future workforce to match the needs of the increasingly higher-tech manufacturing field. The workshop agenda elaborates on that goal:

In bridging the gap between applied research and product development, IMIs will provide shared assets to help companies gain access to cutting-edge capabilities and equipment, and to educate and train students and workers in advanced manufacturing skills. Over a specified period, each IMI will become a self-sustaining technical center of excellence.ENVISION THE FUTURE We look forward to hearing more from Pamela on how the event turned out. It's encouraging to see industry stakeholders host a meeting of the minds to start thinking about how to shift the nation's priorities to emphasize advanced manufacturing.

"Manufacturing is a matter of fundamental importance to the economic strength and national security of the United States," according to a statement on the Advanced Manufacturing Portal. "More than any other industry, a globally competitive manufacturing sector translates inventions, research discoveries and new ideas into better or novel products or processes."

As a company founded on innovation in guided motion technology, we couldn't agree more.

Subscribe to:

Comments (Atom)