TODAY'S TOPIC: Mounting DualVee guide wheels.

We sat down with Mechanical Design Engineer Leslie Lui to discuss the various ways DualVee can be mounted to an application. Over cappuccinos fixed up by our very own marketing department (we're baristas, too) we broke this topic down to a few key points.

At first glance, the typical mounting options for DualVee guide wheels are straightforward. Leslie pointed us to [ page 22 ] of the DualVee catalog for reference (you can also visit our digital copy of the DualVee catalog here).

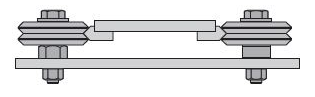

INBOARD mounting is when the guide wheels are placed on the outer edges of a track plate with the vee-edge tracks fitted into the vee-groove. For example:

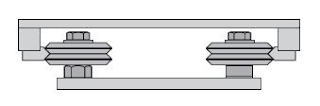

OUTBOARD mounting also fits the vee-track into the guide wheel groove but instead of the wheels being on the outer edge of the track plate, the vee-tracks fit the outer edge of the wheels. This setup puts the wheels inside the aligned vee tracks. Like so:

EXTERIOR mounting involves an entirely different track. These tracks have a groove of their own so the outer edge of the DualVee fits in the track valley, creating a diamond-shaped space between track and wheel. Here's what it looks like:

All of these mountings are created using bushings (standard or low profile) and journals available in both concentric and eccentric versions. This allows for the best possible adjustment for each application. Our application engineers recommend that wheel plate assemblies be constructed with concentric bushings on one side of the plate and eccentric bushings on the opposing side.

But that's just the basics of guide wheel mounting. At Bishop-Wisecarver, we're always looking for out-of-the-box applications. Our imaginations get hungry for something different!

One of our customers doesn't use a track plate at all, Leslie said, instead they use DualVee wheels as guides for wire feeds. Another customer mounted size-0 DualVee guide wheels onto a circular tensioner to wrap paper around transformers. His creative application won one of our video contests — check out the video from last year.

DualVee has also been used for applying a moving load in a press application (pictured below) — no guide tracks needed! Instead, the wheels are being used to apply pressure against a matching 90 degree edge. Now that's different!

Those are just a few examples, but we know more are out there! Our application engineers talk to you every day, and it's always fascinating to us to hear about these unique designs.

Tell us how you reinvented the wheel, so to speak ... or at least reinvented how the wheel is being used. Comment here or email us and we'll feature your feedback on our blog! We will talk to BWC's Project Engineer Brian Burke this week about your feedback and will feature the story in another edition of "Coffee Chat."

*Click on the photo to enlarge* Leslie sketched out for us the various ways a DualVee linear guide wheel can be mounted. You can see in his drawing the different mounting types: "Integral, Swaged and Journal Assemblies," "Integral Bushing” and "Standard” for concentric only, eccentric only and both.